Quality long lasting external lines

There are many kinds of materials that can be used for the line marking of external and internal surfaces. Use of the wrong product or poor application results in poor quality line marking. This can lead to dangerous outcomes and the need for the repainting or repairing of the surfaces, often on a yearly basis. It is therefore critically important to select the right line marking system and specialist installation contractor to avoid these costly and sometimes hazardous mistakes.

As line marking specialists, we often come across line marking where an inappropriate product has been used. For example, the image below shows the damage caused after a short period when a hot-melt line marking solution, without tack coat, is used on concrete.

Thermoplastic lines on concrete painted yearly

These lines need to be constantly updated as they continue to fail. They are repaired by overcoating causing reduced visibility of the line marking and potential trip hazards.

Long-lasting specialist solutions

At inotec UK we provide a range of specialist internal and external line marking solutions that are proven to last for years. Our line-marking and floor painting systems have been developed to offer enduring performance for industrial and logistic applications.

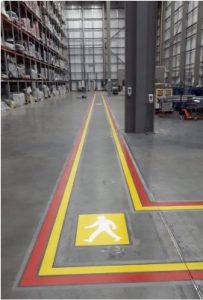

Typical applications for our long-lasting solutions are the line marking of warehouses, car parks, lorry parks, safety areas/walkways, and any other location where durable images are required. Our solutions are specifically designed to fit a broad range of surfaces and environments, including those in ambient, chilled, and sub-zero locations.

Minimal disruption

If you require a fast installation service, many of our robust solutions have very rapid cure times to ensure minimal disruption to operational activities. A recent example of this can be seen in a line marking project we completed for one of the UK’s leading food and drink logistics providers:

The project was undertaken in one of the company’s extremely busy warehouse and distribution centres in Salford. The nine-week project comprised of the installation of over 4,500 linear metres of warehouse floor marking. This included the installation of marshalling lanes, forklift truck routes, zebra crossings, pedestrian walkways and forklift truck and walking men stencils.

The project was delivered within the required timescales and completed on budget. It involved the revamping of the existing line marking of 48 double marshalling lanes each with the capacity to hold 26 pallets, forklift roadways and personnel walkways.

Ultraviolet cured lines minimise operational disruption

To prevent operational downtime the project had to be completed quickly and systematically. Inotec achieved this by putting in place a detailed installation plan to ensure minimal operational disruption whilst the line marking was installed.

The marshalling lanes were revamped each day, three lanes at a time in rectangular blocks along with corresponding roadways and warehouse walkways. They returned to full operation straight after the line marking was completed in each section. This approach meant that, on any given day, only six per cent of the marshalling operation was out of commission.

Enviable reputation

Inotec has developed a reputation for high quality line marking installations, all backed by the performance and customer service expected from a market leading company. For more information on our external and internal line marking solutions take a look at our product range.

If you would like to install line marking within your current or new warehouse facility and you’re not sure what you need, contact inotec UK on 01482 654466 or email info@inotec.co.uk for a consultation with the sales team.

Related articles: How floor marking improves warehouse safety and productivity